Making an Impact with 3D isn’t just a catchy phrase or something you see in fancy movies these days. Nope, it’s way more real and touches our lives in spots you might not even think about. From my corner of the world, messing around with 3D tech for a while now, I’ve seen it jump from being this niche, cool-but-maybe-not-super-useful thing to something that’s genuinely changing how we do stuff, build stuff, and even learn stuff.

Think about it. Not too long ago, if you wanted to build something complex, design a new product, or even make a cartoon character look real, you were stuck drawing endless blueprints, building tiny physical models that took forever, or just hoping your sketches were clear enough for someone else to understand. It was slow, expensive, and honestly, kinda limiting. You couldn’t easily see a mistake until it was maybe too late, or you couldn’t quickly try out a wild idea just to see if it worked.

Then came 3D technology, and suddenly, you could build things layer by layer, digitally or physically, with crazy accuracy. You could design intricate shapes that were impossible before. You could visualize ideas in a way everyone could grasp, not just the folks who were good at reading flat drawings. This shift? It wasn’t just a small upgrade; it was a total game-changer for Making an Impact with 3D in so many fields.

My own journey into 3D started small, tinkering with software, trying to model simple objects. It felt like playing with digital clay. But the more I messed around, the more I saw the potential. It wasn’t just about making cool pictures. It was about solving problems, creating solutions, and yes, truly Making an Impact with 3D in ways that felt meaningful.

Let’s dive into some of the places where this magic happens. We’ll look at how 3D technology is shaking things up, making stuff better, faster, and sometimes, just plain cooler. It’s pretty wild when you start adding it all up.

Designing the Future, Faster: How 3D Helps Ideas Take Shape

One of the biggest spots where I’ve seen 3D make a massive difference is in design and prototyping. Back in the day, coming up with a new gadget, a piece of furniture, or even a car part meant sketches, then detailed 2D drawings, then maybe a physical model made from wood or foam. That physical model? Took ages to build, couldn’t be easily changed, and if you found a problem, you often had to start over or make difficult adjustments. It was a bottleneck.

Making an Impact with 3D completely changed this. Now, designers can create a detailed, digital 3D model of literally anything on a computer screen. This model isn’t just a picture; it’s data. You can spin it around, look at it from any angle, zoom in on tiny details. You can test how parts fit together without ever touching a physical object. You can see how light bounces off a surface, how a design looks in different colors or materials, all before anything is actually made.

This digital playground speeds things up unbelievably. A designer can make a change in minutes that used to take days or even weeks to redraw and rebuild. They can try dozens of variations of a design to find the absolute best one, instead of just picking the first decent idea because making changes is too much hassle. This makes the design process way more creative and efficient.

But it doesn’t stop in the digital world. Once you have that 3D model, you can send it straight to a 3D printer. Suddenly, you can have a physical version of your design in your hands in hours, not days or weeks. This prototype might not be the final material, but it lets you feel the shape, check the size, and see how it actually works in the real world. Found a problem? Hop back into the 3D software, tweak the model, and print a new version. This is rapid prototyping, and it’s a huge part of Making an Impact with 3D in product development.

I remember one project where we were working on a complex part with weird curves. Trying to explain it with 2D drawings was a nightmare. People just couldn’t visualize how it all fit together. But when we showed them the 3D model, spinning it around on the screen, suddenly everyone got it. We then printed a few versions, making tweaks based on feedback, and the final design was nailed down so much faster and with fewer mistakes than if we’d gone the traditional route. This ability to visualize and quickly iterate is fundamental to Making an Impact with 3D in this space.

This speed and flexibility mean companies can bring new products to market much faster. They can test ideas with less risk and less cost. It empowers small businesses and even individuals to develop and test their own inventions and designs without needing huge manufacturing budgets upfront. That’s a pretty significant impact, wouldn’t you say?

Building Anything Imaginable: 3D Printing Beyond Prototypes

While prototyping is huge, Making an Impact with 3D goes way beyond making test models. 3D printing, or additive manufacturing as the pros call it, is increasingly being used to make final products, not just prototypes. This is where things get really interesting, especially when you consider complex parts or custom items.

Traditional manufacturing often involves cutting material away (like machining metal) or using molds (like injection molding plastic). These methods are great for making thousands or millions of the same simple thing. But what if you need a super complex shape that’s impossible to cut? What if you only need one or two of something highly specialized? What if you need something perfectly fitted to an individual?

That’s where Making an Impact with 3D comes into play for actual manufacturing. 3D printers can build objects layer by layer, adding material only where it’s needed. This means they can create shapes with internal structures, hollow spaces, and complex geometries that were previously impossible or incredibly expensive to make. Think about lightweight but strong parts for airplanes or cars, or intricate components for medical devices.

I’ve seen examples where engineers used 3D printing to combine multiple parts that used to require assembly into a single, stronger, lighter printed part. This reduces assembly time, lowers the chance of failure points, and saves on material waste. This is Making an Impact with 3D by literally reinventing how things are built.

Consider personalized products. In the past, if you needed a medical implant, like a hip replacement, it came in a few standard sizes. Now, surgeons can use scans of a patient’s body to create a perfectly customized implant that fits their unique anatomy precisely. This leads to better outcomes and faster recovery. This level of personalization, made possible by 3D scanning and printing, is a profound way 3D is making a difference in people’s lives.

It’s also shaking up industries like aerospace. Aircraft parts need to be incredibly strong but also as light as possible to save fuel. 3D printing allows engineers to design parts with intricate lattice structures inside – strong like bone, but much lighter than a solid block of metal. Making an Impact with 3D in critical areas like this is literally helping planes fly more efficiently.

Even in consumer goods, we’re starting to see more personalized items, custom-fitted headphones, unique jewelry, or even specialized tools. The ability to produce items on demand, tailored to exact specifications, is a significant shift from mass production. This shift, enabling bespoke creation, is a powerful demonstration of Making an Impact with 3D.

Bringing Imaginary Worlds to Life: 3D in Entertainment

Okay, let’s talk about the fun stuff! When most people think of 3D, they often think of movies, video games, and animation. And for good reason! Making an Impact with 3D in the entertainment world is huge and probably the most visible application for many folks.

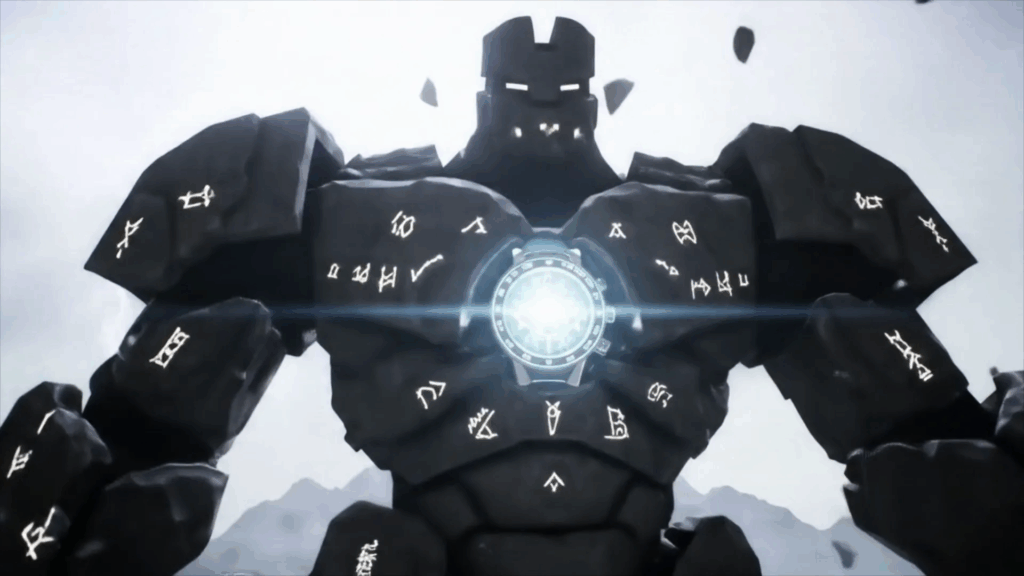

Remember those animated movies from decades ago? They were beautiful, hand-drawn. Then came computer animation, and suddenly characters and worlds had depth and looked more realistic. Now, with advanced 3D modeling, texturing, lighting, and animation techniques, the visuals in movies and games are absolutely mind-blowing. Characters look incredibly lifelike, environments are vast and detailed, and special effects are seamlessly integrated into live-action footage.

It’s not just about making things look pretty, though. Making an Impact with 3D here is about storytelling. It allows creators to build entire universes from scratch, bringing fantastical creatures, impossible landscapes, and complex action sequences to life in a way that wasn’t possible with traditional methods. They can control every aspect of the visual world, creating immersive experiences that pull you right in.

In video games, 3D graphics are fundamental. They allow for open-world environments you can explore, complex character interactions, and realistic physics that make the game feel more responsive and believable. The evolution of game graphics, from simple 2D sprites to photorealistic 3D worlds, is a clear indicator of the impact 3D technology has had.

Beyond the screen, 3D is also used extensively in theme parks and attractions to create immersive rides and experiences. It’s used in virtual reality (VR) and augmented reality (AR), which are just starting to scratch the surface of their potential for gaming, simulation, and interactive entertainment. VR, for example, allows you to step *inside* a 3D environment, offering a level of presence and immersion that 2D screens can’t match. This is a powerful new way of Making an Impact with 3D by changing how we experience digital content.

I’ve had the chance to work on some visualization projects that, while not blockbuster movies, used 3D to tell a story or explain a complex idea visually. Showing someone how something works by letting them fly around a 3D model of it is infinitely more effective than just describing it or showing diagrams. That ability to communicate complex ideas through engaging visuals is a key part of Making an Impact with 3D in this sector.

And let’s not forget the independent artists and animators. Affordable 3D software and powerful computers mean that individuals or small teams can create professional-quality animation and visual effects that used to require massive studios. This democratizes creation, letting more voices and visions come to life. That accessibility is a huge part of Making an Impact with 3D for the creative community.

Making Learning Tangible: 3D in Education and Training

Imagine trying to learn about the human heart from a flat diagram in a book. You can see the basic parts, but it’s hard to understand the complex chambers and how they work together. Now, imagine being able to explore a detailed, interactive 3D model of the heart, spinning it around, taking it apart layer by layer, seeing the blood flow through it. That’s the difference 3D is Making an Impact with 3D in education.

3D technology is a fantastic tool for making complex concepts understandable and engaging. It allows students to visualize things they couldn’t otherwise see – like the structure of a molecule, the layers of the Earth, or how a machine engine works. Instead of just reading about it, they can interact with it in a virtual space.

Medical students can practice complex surgeries on 3D printed models or in VR simulations before ever touching a real patient. Engineering students can virtually assemble and test designs. Architecture students can walk through their building designs before they’re built. This hands-on (or virtual-hands-on) experience makes learning much more effective and memorable.

I’ve seen how 3D models can light up a student’s face when they finally grasp a concept that was confusing them. It turns abstract ideas into concrete, visual realities. This is particularly helpful for subjects like science, technology, engineering, and math (STEM), where spatial reasoning is key.

Beyond traditional schooling, 3D is also being used for professional training. Training simulations for pilots, surgeons, factory workers, or emergency responders are becoming more realistic and effective thanks to 3D graphics and environments. People can practice dangerous or complex tasks in a safe, controlled virtual space, learning from mistakes without real-world consequences. This improves safety and proficiency.

Think about training someone to operate a piece of heavy machinery. Instead of just reading a manual or watching a video, they can train in a realistic 3D simulation that mimics the actual equipment and environment. They can learn the controls, practice maneuvers, and respond to different scenarios. This is a very practical way 3D is Making an Impact with 3D by preparing people for jobs and situations.

Creating these educational and training materials requires expertise in both the subject matter and 3D technology. It’s a collaboration between educators, trainers, and 3D artists or developers to build these immersive learning experiences. The potential here is massive, making education more accessible and effective for people of all ages and in all fields.

Visualizing and Building Smarter: 3D in Architecture and Construction

Building things, especially large and complex structures, has always involved a lot of planning and visualization. Traditionally, architects and builders relied on blueprints and scaled physical models. While these work, they have limitations. It can be hard for clients (who aren’t trained to read complex plans) to fully grasp the final result, and coordinating all the different trades and systems (plumbing, electrical, HVAC) on a large project is incredibly challenging with just 2D drawings.

Making an Impact with 3D has revolutionized this. Building Information Modeling (BIM) is a process that uses 3D models to represent every aspect of a building project, from the structure and walls to the pipes and wiring, and even the furniture. This isn’t just a pretty picture; it’s a database linked to the 3D geometry. Every element in the 3D model has information attached – what it is, what material it’s made of, who makes it, how much it costs, when it needs to be installed.

This comprehensive 3D model allows everyone involved in a construction project – architects, engineers, contractors, and clients – to visualize the building clearly. Clients can take a virtual walk-through of the proposed building, getting a real feel for the space, the light, and the layout. This helps them provide better feedback early in the design process, avoiding costly changes later on.

For the construction team, the 3D model helps identify potential conflicts between different systems (like a pipe running into a structural beam) before construction even begins. Finding and fixing these clashes in the digital model is far cheaper and faster than discovering them on the job site when concrete has already been poured. This prevents delays, reduces waste, and saves money. This collision detection and planning capability is a critical way Making an Impact with 3D streamlines construction.

Furthermore, 3D scanning can be used to create accurate models of existing buildings or construction sites. This data can be used for renovations, verifying that construction matches the plan, or monitoring progress. It provides a digital twin of the real-world site, which is invaluable for planning and quality control.

I’ve seen projects where using a 3D BIM model from the start made the entire process smoother. Communication among the team was better because everyone was looking at the same detailed 3D representation. Issues were caught early. The client was happier because they could truly visualize the finished building. This move towards integrated 3D workflows is profoundly changing how buildings are designed, planned, and constructed, truly Making an Impact with 3D in the built environment.

Some companies are even starting to use 3D printing on-site for certain building components or even entire small structures, opening up new possibilities for unique designs and faster construction times. While still in early stages for large-scale buildings, the potential for 3D printing to disrupt traditional construction methods is significant, adding another layer to how 3D is Making an Impact with 3D in this industry.

Improving Health and Healing: 3D in Medicine

Perhaps one of the most amazing and life-changing areas where Making an Impact with 3D is happening is in healthcare. This isn’t science fiction anymore; it’s real-world stuff that’s helping doctors, training surgeons, and improving patient care in incredible ways.

We touched on custom implants earlier, but let’s dig a bit deeper. Using medical imaging like CT scans or MRIs, doctors can create detailed 3D models of a patient’s organs, bones, or even tumors. These models allow them to see things from every angle, plan complex surgeries with greater precision, and even explain a condition or procedure to the patient in a way they can easily understand. Seeing a 3D model of your own anatomy and the problem helps patients feel more informed and less anxious. This visualization is a powerful tool in Making an Impact with 3D on patient understanding and care.

For surgeons, having a 3D model of the area they’re operating on is like having a roadmap. They can use the model to practice the surgery beforehand, identifying potential challenges and planning the best approach. In some cases, 3D printed models are created as exact replicas of a patient’s anatomy, allowing surgeons to physically hold and examine the area they will be working on before the actual operation. This practice can reduce surgical time, minimize complications, and improve outcomes. This direct application of 3D technology in surgical planning is a literal life-saver, showcasing the profound Making an Impact with 3D in medicine.

3D printing is also being used to create custom surgical guides and tools. These are precisely shaped devices, printed based on the patient’s 3D scans, that help surgeons make more accurate cuts or place implants exactly where they need to go. This is particularly valuable in complex procedures like bone surgery.

Beyond surgery, 3D printing is being used for prosthetics. Instead of standard, uncomfortable artificial limbs, patients can receive lightweight, custom-fitted prosthetics that are designed and printed to match their specific needs and body shape. This improves comfort, function, and even aesthetics. Making an Impact with 3D by providing personalized medical devices is changing lives for the better.

Researchers are even exploring 3D bioprinting, which involves printing with living cells to create tissues and organs. While still in early stages, the long-term potential to create replacement organs or tissues is incredibly exciting and represents the ultimate frontier of Making an Impact with 3D in healthcare.

The combination of 3D imaging, modeling, simulation, and printing is transforming medicine. It’s enabling more precise diagnosis, better surgical planning, improved training, and personalized patient care. It’s a field where the impact of 3D technology is literally measured in saved lives and improved quality of life.

Exploring the Unseen: 3D in Science and Research

Scientists and researchers are constantly trying to understand things that are too small to see, too large to comprehend all at once, or simply too complex to visualize from flat data. This is another area where Making an Impact with 3D is opening up new possibilities.

Microscopic structures, like the intricate shapes of proteins or the connections between neurons in the brain, can be visualized in 3D, allowing researchers to study their form and function in unprecedented detail. Instead of looking at slices, they can see the whole structure. This is critical for understanding diseases, developing new drugs, and advancing our knowledge of biology and chemistry. Making an Impact with 3D by making the invisible visible is accelerating discovery.

On the other end of the scale, astronomers can use 3D data to model the structure of galaxies, the distribution of dark matter, or the formation of stars. Geologists use 3D modeling to understand rock formations, underground water flow, or seismic activity. Climatologists can visualize complex atmospheric or ocean currents in 3D. Being able to see these massive, complex systems in a navigable 3D space helps scientists identify patterns, test hypotheses, and communicate their findings more effectively.

Researchers are using 3D printing to create specialized lab equipment, custom-designed components for experiments, or even miniature environments for studying biological processes. This allows them to build tools precisely tailored to their needs, often much faster and cheaper than ordering custom parts through traditional manufacturing. The ability to rapidly create specialized equipment is a significant way Making an Impact with 3D speeds up the research process.

Data visualization is a huge part of modern science. As scientists collect vast amounts of data from experiments, simulations, or observations, 3D visualization tools help them make sense of it. Presenting complex datasets as interactive 3D models can reveal insights that would be hidden in tables or graphs. This is vital for identifying trends, outliers, and relationships within the data.

I’ve seen how researchers get excited when they see their data transformed into a compelling 3D model. Suddenly, they see connections they didn’t notice before. It sparks new questions and ideas. That power to illuminate complex information is a key way 3D is contributing to scientific progress, truly Making an Impact with 3D in the pursuit of knowledge.

Whether it’s understanding the tiniest building blocks of life or the vastness of the cosmos, 3D technology provides scientists with powerful tools to explore, analyze, and communicate their findings. It’s expanding the frontiers of human knowledge.

Preserving the Past, Creating the New: 3D in Art and Culture

Art has always evolved with technology, and 3D is no different. Artists are using 3D tools to create digital sculptures, complex installations, and unique visual effects that push the boundaries of what’s possible. Digital 3D art exists purely in the virtual realm, shared and experienced on screens or in VR. Physical 3D printing allows digital sculptures to be brought into the real world, enabling artists to create forms that would be incredibly difficult or impossible to sculpt by hand.

Making an Impact with 3D in art isn’t just about creating new things; it’s also about preserving the past. Museums and cultural heritage sites are using 3D scanning to create incredibly detailed digital replicas of artifacts, sculptures, and even entire historical buildings. These 3D models serve multiple purposes.

First, they act as a digital archive, preserving these treasures for future generations even if the physical objects are damaged or lost. Second, they allow people from anywhere in the world to virtually explore these artifacts and sites online, democratizing access to culture and history. Third, 3D models can be used for conservation planning, allowing experts to study damage or plan restorations with great precision. This preservation and accessibility aspect is a significant way Making an Impact with 3D benefits culture.

3D printing can also be used to create replicas of artifacts for study or display, allowing people to handle and examine objects that would normally be too fragile or valuable to touch. Schools and smaller museums can use 3D printed replicas to enhance their educational programs, providing tangible examples of historical items.

Beyond preservation, artists are using 3D scanning of real-world objects or people as a starting point for their digital creations, blending the physical and virtual worlds. This opens up new avenues for artistic expression and experimentation. Making an Impact with 3D by blending these realities allows for entirely new forms of art to emerge.

From creating intricate digital sculptures to bringing historical sites to life online, 3D technology is both a tool for new artistic creation and a powerful means of preserving and sharing our cultural heritage. It’s enabling artists and cultural institutions to connect with audiences in new and engaging ways, demonstrating another facet of Making an Impact with 3D.

Making the World More Accessible: 3D for Everyone

This is a really important one, and often less talked about. Making an Impact with 3D isn’t just for big industries; it can also make the world more accessible for people with disabilities.

We already mentioned custom prosthetics, which significantly improve the quality of life for individuals who have lost limbs. But 3D goes further. People with visual impairments can benefit from 3D printed tactile maps, models of objects, or even artwork that they can explore by touch, allowing them to experience things they couldn’t see. This opens up access to information and experiences in museums, public spaces, and educational settings.

3D printing can be used to create custom assistive devices tailored to an individual’s specific needs – things like specialized grips for tools, custom mounts for phones or tablets, or unique adaptive equipment for sports or hobbies. These devices can be designed and produced relatively quickly and inexpensively compared to traditional methods, Making an Impact with 3D by providing personalized support.

For architects and urban planners, 3D modeling can be used to simulate accessibility challenges. They can model wheelchair ramps, door clearances, and pathway slopes in 3D to ensure that buildings and public spaces are truly navigable and welcoming for everyone, not just those without mobility issues. This foresight in design, enabled by 3D visualization, is crucial for creating inclusive environments.

3D printing also allows for the creation of replacement parts for adaptive equipment that might otherwise be expensive or difficult to obtain. If a small, critical piece of a mobility aid breaks, it can potentially be 3D printed, allowing for faster repairs and reducing downtime for the user. This practical application of 3D is a quiet but significant way it’s Making an Impact with 3D on daily life for many.

The ability to visualize, design, and create custom physical objects is key here. It means solutions can be tailored to the individual, rather than forcing individuals to adapt to generic solutions. This personalized approach, empowered by 3D technology, is a powerful force for improving accessibility and independence, truly Making an Impact with 3D on people’s lives.

As the technology becomes more accessible and affordable, we can expect to see even more innovative ways 3D is used to break down barriers and create a more inclusive world for everyone. It’s a beautiful example of technology being used for good.

Selling with Sight: 3D in Marketing and Sales

In the world of selling things, getting people to see and understand what you’re offering is everything. And plain old pictures or descriptions can only go so far. This is where Making an Impact with 3D is really changing the game in marketing and sales.

Instead of just showing a flat image of a product, companies can now provide interactive 3D models online. Customers can spin the product around, zoom in, see it from every angle, and even customize options like color or features in real-time. This provides a much richer and more informative shopping experience, especially for complex items like furniture, cars, or electronics. Allowing customers to truly interact with a virtual version of the product is a significant way 3D is Making an Impact with 3D on e-commerce and online sales.

Augmented reality (AR), which uses 3D technology to overlay virtual objects onto the real world through your phone or tablet camera, is becoming increasingly popular in retail. Imagine pointing your phone at your living room and seeing how a new couch or painting would look in that space before you buy it. Or trying on virtual clothes or makeup using AR filters. This helps customers make more confident purchase decisions and reduces returns. AR’s ability to bring 3D products into the customer’s environment is a powerful sales tool.

For businesses selling large or complex systems, like manufacturing equipment or industrial machinery, 3D visualizations and animations are invaluable for explaining how their products work. Showing a 3D animated cutaway of a machine, demonstrating its internal mechanisms, is far more effective than trying to explain it with diagrams and text. This clarity in communication is a key part of Making an Impact with 3D in B2B sales.

Real estate is another area seeing a big change. Instead of just looking at photos, potential buyers or renters can take virtual 3D tours of properties online. This saves time for both the agent and the client and allows people to view properties from anywhere in the world. For properties that haven’t been built yet, architects and developers use 3D renderings and virtual reality walkthroughs to help potential buyers visualize the finished building and their future home. This ability to pre-sell spaces based on realistic 3D models is a huge advantage in the market, clearly demonstrating Making an Impact with 3D on real estate.

Trade shows and exhibitions are also using 3D technology for interactive displays and product demos. Rather than shipping heavy equipment, companies can showcase fully functional 3D simulations or interactive models that visitors can explore. This is more engaging and often more practical.

Making products and spaces more visually accessible and interactive through 3D technology helps capture attention, build customer confidence, and ultimately drive sales. It’s changing how businesses present themselves and how customers shop and explore.

Bringing Things Back: 3D in Repair and Restoration

Sometimes, things break. Sometimes, they are old and parts are no longer made. This happens with everything from antique furniture and classic cars to industrial machinery and even household appliances. Finding replacement parts can be a major headache, if not impossible. This is where 3D technology is stepping in to help with repair and restoration, showing a different angle of Making an Impact with 3D.

If a specific part is broken or missing, and there’s another identical part (or the broken one can be scanned), 3D scanning can create a digital model of that part. That model can then be adjusted or repaired digitally if needed, and finally, 3D printed using the appropriate material (plastic, metal, etc.) to create a new, functional replacement part. This is incredibly useful for rare or custom-made items where traditional manufacturing methods would be prohibitively expensive or impossible.

Imagine restoring a vintage car and needing a small, unique plastic knob for the dashboard. Finding an original might take years and cost a fortune. If you have another knob or can scan the broken one, you can 3D print a perfect replacement. This capability is a game-changer for hobbyists, repair shops, and industries dealing with legacy equipment. It’s a tangible way 3D is Making an Impact with 3D by extending the life of objects.

For historical items or artworks, 3D scanning helps conservators understand the object’s structure and damage without physically touching it extensively. They can create 3D models to plan restoration work or even print temporary supports or jigs specifically designed for the fragile object they are working on. Precision is key in this delicate work, and 3D tools provide that precision.

Even in manufacturing settings, if a critical but non-standard part on an assembly line breaks, and ordering a new one takes weeks, being able to 3D print a temporary (or even permanent, depending on the material) replacement can save massive amounts of downtime and lost production. This ability to rapidly fabricate needed components is a practical, cost-saving application of 3D, making an immediate impact.

Making an Impact with 3D in repair and restoration is all about enabling the fix, preserving the original, and extending the usable life of items that might otherwise be discarded. It requires a combination of scanning, modeling, and printing skills, but the ability to recreate or repair unique parts is incredibly valuable.

Thinking Outside the Box: 3D in Food and Fashion

Yep, even industries like food and fashion are getting in on the 3D action! It might sound a bit weird at first, but there are some cool and innovative ways Making an Impact with 3D is showing up here.

In fashion, designers are using 3D software to create virtual prototypes of clothing and accessories. They can drape fabrics digitally, test fits and patterns on 3D avatars, and visualize designs before any physical material is cut. This reduces waste and speeds up the design process. Some designers are even creating entire digital-only fashion collections for virtual worlds or social media filters, showcasing a completely new kind of fashion made possible by 3D.

3D printing is also being used to create unique elements for clothing and accessories – intricate lace patterns, complex shoe soles, or even entire garments made from flexible 3D printed materials. This allows for designs that would be impossible with traditional sewing and tailoring. Making an Impact with 3D in fashion is enabling designers to explore new forms, textures, and structures.

Now, food. Yes, 3D printed food is a thing! While maybe not ready for your everyday dinner table yet, 3D food printers can create intricate shapes and patterns out of ingredients like chocolate, dough, or even vegetable purees. This is mostly used for decorative purposes in high-end restaurants or for creating novelty items. However, there’s also research into using 3D printing for creating customized meals with specific nutritional content, which could be valuable in hospitals or for individuals with specific dietary needs. Imagine printing a meal tailored exactly to a patient’s requirements!

Another application is creating custom molds for food production, like intricate chocolate molds or pastry forms, using 3D printing. This allows for unique shapes that would be difficult to produce otherwise.

While these applications might seem more niche compared to manufacturing or healthcare, they demonstrate the versatility of 3D technology and how it can be applied in creative and unexpected ways, showing yet another dimension of Making an Impact with 3D in diverse fields.

Understanding Complex Systems: 3D in Simulation and Analysis

Beyond just visualization, 3D technology is crucial for creating realistic simulations that help us understand how things work or predict outcomes. This is a powerful way Making an Impact with 3D helps in fields ranging from engineering to urban planning to climate science.

Engineers use 3D models to run simulations testing how a product will perform under stress, how fluid will flow through a pipe system, or how heat will dissipate from an electronic component. Instead of building and breaking multiple physical prototypes, they can test countless scenarios virtually, saving time and money and leading to better, safer designs. This virtual testing and analysis capability is a fundamental aspect of Making an Impact with 3D in product development and safety.

Urban planners use 3D models of cities to simulate traffic flow, pedestrian movement, sunlight patterns, or the impact of new buildings on the existing environment. This helps them make informed decisions about urban development, ensuring cities are functional, efficient, and pleasant to live in. Visualizing these complex interactions in a 3D environment is far more effective than looking at maps and charts.

Environmental scientists use 3D simulations to model climate change impacts, pollution dispersion, or ecological systems. These complex models require vast amounts of data and sophisticated 3D visualization to understand the results and communicate them to policymakers and the public. Making an Impact with 3D here is literally helping us understand and respond to global challenges.

Even in entertainment, physics simulations using 3D are essential for creating realistic visual effects – think of simulating explosions, water splashes, or collapsing buildings in a movie. These simulations add a layer of realism that makes the impossible look believable.

The power of 3D in simulation lies in its ability to represent complex, multi-dimensional data and systems in a way that is intuitive to understand and analyze. It allows us to ask “what if” questions in a virtual environment and see the potential consequences, helping us make better decisions in the real world. This analytical and predictive power is a core component of Making an Impact with 3D.

Making an Impact with 3D, One Person at a Time: Personal Use and Hobbies

While we’ve talked a lot about big industries and professional applications, it’s important not to forget that Making an Impact with 3D is also happening at a very personal level. The rise of affordable 3D printers and more accessible 3D software has put this technology into the hands of hobbyists, makers, and individuals who are using it in creative and practical ways in their everyday lives.

People are designing and printing custom items for their homes – replacement parts for broken appliances (see, restoration applies here too!), organizers for drawers, unique decorations, or even custom-fitted phone cases. If you can imagine it and model it, you can potentially print it. This ability to create exactly what you need, rather than buying something off the shelf that’s “close enough,” is a powerful kind of personal impact.

Hobbyists are using 3D printing for everything from creating custom miniatures for tabletop games, building detailed models (like planes, trains, and automobiles!), or making unique components for robotics and electronics projects. The level of detail and customization possible with 3D printing opens up entirely new possibilities for crafting and building.

Artists who don’t have access to traditional sculpting materials or techniques are using 3D modeling and printing to bring their artistic visions to life. Musicians are 3D printing custom instrument parts or accessories. Parents are 3D printing unique toys or educational aids for their kids. The applications are truly limited only by imagination.

I’ve personally used my 3D printer to fix things around the house, create custom parts for projects, and just make fun little gadgets. There’s a real sense of satisfaction in designing something on a computer and then holding the physical object you created just a few hours later. This personal empowerment, the ability to be a creator and a problem-solver in your own space, is a wonderful example of Making an Impact with 3D.

The maker movement, fueled in large part by affordable 3D printing, is about creativity, learning, and sharing knowledge. It’s about empowering individuals to become producers, not just consumers. This grassroots level of innovation and creation is a significant part of the broader impact that 3D technology is having on society, making it accessible for anyone to start Making an Impact with 3D in their own way.

Conclusion: The Ever-Growing World of Making an Impact with 3D

So, where does all this leave us? It’s clear that Making an Impact with 3D is happening all around us, often in ways we don’t immediately recognize. It’s not just about cool movies or sci-fi gadgets anymore. It’s a fundamental technology that’s changing how we design, manufacture, heal, learn, sell, and even play.

From speeding up product development and enabling personalized medicine to preserving ancient artifacts and empowering individual creators, the reach of 3D technology is incredibly broad. The ability to translate digital ideas into physical form, to visualize complex data in an intuitive way, and to create things with unprecedented precision and customization is a powerful force for innovation.

As 3D scanning, modeling, software, and printing technologies continue to improve and become more affordable, we can expect to see even more incredible applications emerge. The lines between the digital and physical worlds are blurring, and 3D technology is a key part of that transformation.

For anyone looking to get involved, whether it’s as a designer, engineer, artist, healthcare professional, or just a curious hobbyist, there are more resources and opportunities than ever before to learn about and start using 3D technology. The barriers to entry are lower than they’ve ever been.

Making an Impact with 3D is an ongoing story, a continuous evolution of how we use technology to solve problems, create beauty, and improve lives. It’s exciting to be a part of it and to see what comes next.

If you’re interested in learning more or exploring the possibilities yourself, there are tons of resources out there. You can start by checking out sites like www.Alasali3D.com or diving specifically into how this technology makes a difference by exploring www.Alasali3D/Making an Impact with 3D.com. The journey into the world of 3D is fascinating, and the potential to make a real difference is vast.

Making an Impact with 3D isn’t just a concept; it’s something that’s being lived out every day by people using this incredible technology to build a better future.